OEC has taken initiatives to develop Biotechnology Processes for Generation of Gaseous and Liquid Fuels from various sources like Lignite, unrecovered Oil, and Coal etc. To carry out experimental work on various research activities relating to microbial processes, OEC has set up laboratory facilities at Delhi and Dehradun; for initial testing, characterization and modeling (Delhi) and experimental work (Dehradun) for some of the R&D projects in biotechnology.

Bio-stimulation of CBM well JH#1, Jharia

Bio-stimulation of CBM well JH#1, Jharia

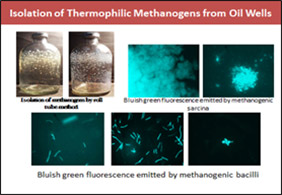

It is estimated that a significant quantity of oil remains unrecovered in mature fields due to various reasons. One of the probable approaches is to convert the unrecovered reservoir oil to methane gas in-Situ by using bio conversion methods with the help of microorganisms. Under this project thermophillic, anaerobic methanogenic bacterial, consortium, capable of producing methane gas using oil as carbon substrate are to be isolated. Experiments have been started.

India is world’s third largest producer of coal. The reserves in India are estimated at around 298.94 billion tons, as on 31.03.2013. As per Directorate General of Hydrocarbons (DGH) database, India has estimated 92 Trillion Cubic Feet of Coal Bed Methane (CBM) gas reserves, however commercial production of CBM is still at a very nascent stage in the country. ONGC is currently operating in four CBM Blocks i.e., Jharia, Bokaro, North Karanpura and Raniganj. It is estimated that on an average only 15-20% of the coal is recoverable and rest of it lies unexploited. The utilization of biotechnological processes can be one of the promising approaches to convert low rank or unrecoverable coal into methane. It is recognized that methane generating bacteria can act on coal seams to produce biogas, comprising mainly methane and carbon dioxide gas.

OEC in association with TERI has developed and demonstrated the microbial process for enhancement of gas in CBM well (JH#1) at Jharia. The Microbial and stable gas isotope analysis data support the stimulation of microbial communities and in-situ biological gas production. The field experiments have demonstrated that there is many fold increase in gas production and the enhanced activity of methanogens leads to additional/enhanced methane generation in coal seams.

OEC in association with TERI has developed and demonstrated the microbial process for enhancement of gas in CBM well (JH#1) at Jharia. The Microbial and stable gas isotope analysis data support the stimulation of microbial communities and in-situ biological gas production. The field experiments have demonstrated that there is many fold increase in gas production and the enhanced activity of methanogens leads to additional/enhanced methane generation in coal seams.

Therefore, microbially stimulated CBM can increase the longevity and productivity of the CBM fields. The experimental wells in Jharia are producing gas at enhanced levels for more than 18 months. OEC is continuing with various field experiments to enhance the gas production from different CBM wells. R&D projects on microbial oil production from oleaginous yeast have been taken up at R&D facilities at Dehradun and Delhi. Proof of Principle experiments have established microbial conversion of oil to gas. The process is currently under optimization for scale up experiments.

OEC, under collaborative projects with Agarkar Research Institute (ARI) Pune, has developed specialized microbial culture bank with 124 methanogens and 52 hydrolytic bacteria for energy recovery from lignite and matured oil reservoirs. Under another innovative project with ARI bacteriophages that can inhibit the growth of sulfate, reducing bacteria for mitigation of reservoir souring as well as microbial induced corrosion has been isolated and dose optimization related experiments are in progress.