Biotechnology Programme of OEC aims to develop Biotechnology-based processes for Generation of Gaseous and Liquid Fuels from various sources like Lignite, Coal, Unrecovered Oil, etc. in the hydrocarbon reservoirs. To carry out the experimental research activities relating to microbial processes, Bio Energy Research Laboratory facilities of OEC was established at KDMIPE Dehradun for in-house projects.

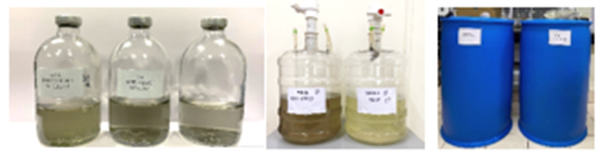

It is a well-known fact that significant quantities of oil is left unrecovered in the reservoir even after tertiary recovery methods. One of the probable approaches to recover energy from such unrecovered oil source is converting it to methane gas by using in-situ bioconversion methods with the help of indigenous microorganisms. Under this project, thermophilic, anaerobic methanogenic bacterial consortium, capable of producing methane gas using oil as carbon substrate, were isolated and media recipe was tailored for the growth of developed consortium along with optimization of the process parameters. The developed bioprocess is under testing phase at Ankleshwar field of ONGC.

India is world’s third largest producer of coal however, commercial production of CBM is still at a very nascent stage in the country. ONGC is currently operating in four CBM Blocks i.e., Jharia, Bokaro, North Karanpura and Raniganj. It is estimated that on an average, only 15-20% of the coal is recoverable and rest of it lies unexploited. The utilization of biotechnological processes can be one of the promising approaches to convert low rank or unrecoverable coal into methane. It is established that methane generating bacteria can act on coal seams to produce biogas, comprising of mainly methane and carbon dioxide gas. OEC in collaboration with TERI has developed and demonstrated the microbial process for the enhancement of gas in CBM wells at Jharia and Bokaro field. The carbon isotope analysis data support the stimulation of microbial communities and in-situ biological gas production. The enhanced activity of methanogens lead to additional/enhanced methane generation in coal seams and the field testing has demonstrated 2-4 fold increase in gas production. The developed bioprocess would be a big leap in not only increasing the longevity, but also the productivity of the CBM fields. R&D efforts have been also initiated in collaboration with TERI for bioconversion of CO2 to methane reported in some CBM wells of Bokaro Asset.

OEC in collaboration with Agharkar Research Institute (ARI), Pune has developed another innovative bioprocess to inhibit the growth of sulfate reducing bacteria (SRB) for mitigation of reservoir souring as well as microbial induced corrosion (MIC). The developed bioprocess is ready to be tested in selected installations/well/pipeline of Western Offshore.