The institute “Institute of Production Engineering & Ocean Technology” (IPEOT), has come into existence on 31st August 2023 post the merger of Institute of Oil and Gas Production Technology (IOGPT) and the Institute of Engineering and Ocean Technology (IEOT) to bring about resources optimization and foster a more streamlined & cohesive approach towards achieving ONGC's organizational objectives.

The Institute of Oil & Gas Production Technology (IOGPT) was established in 1984 under assistance from UNDP and ADB to meet the production and processing related technological requirement of Oil and Gas fields and processing plants. The Institute of Engineering and Ocean Technology (IEOT) was founded in 1983 for innovation, development and acceleration of the future plans of ONGC to achieve self- reliance in technology.

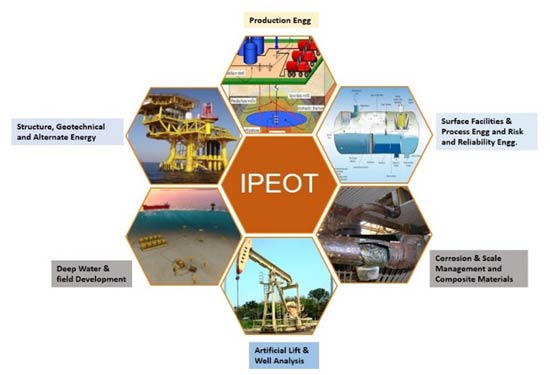

Expertise:

The major strength of the institute lies in its highly qualified, trained and experienced technical manpower which has a harmonious blend of youth and experience, who are equipped to take up any challenge in the field of hydrocarbon production and processing. Equipped with a combination of technical strength, state of the art laboratories & software, the institute commands a unique place in the following areas.

- Well stimulation, Sand control, Well completion / intervention and water/gas shut off

- Analysis, modelling and simulation of surface facilities & process systems including HAZOP, HAZID, QRA studies.

- Failure Analysis of pipelines, downhole tubular and equipment. Selection of Material of Construction for severe corrosive conditions. Scale Management.

- Conceptualization, selection & optimization of artificial lift systems

- Development of onshore and offshore fields, in shallow as well as deep water

- Life Extension & Structural Integrity Assessment of offshore structures and Geotechnical investigations for offshore platforms.

Apart from catering to the needs of the Assets, Basins & Plants of the parent organization, IPEOT’s clientele includes Joint Venture companies, ONGC Videsh and other commercial entities in the Oil & Gas sector. Quality, reliability and timely completion of projects are Institute's forte. The institute has completed more than 5500 R&D projects and numerous short term studies towards production enhancement and systems improvement. The institute has 29 Patents & 22 Copyrights and is associated with IITs and other renowned research institutes for R&D activities.

Core Functional Areas

2. Technologies upgraded/ inducted:

- Development of environment friendly alternate Solvent for Asphaltene removal

- Development of suitable enzyme based breaker for frac fluid used in CBM

- Development of Novel Single Phase Retarded Acid System for Stimulation of Limestone Reservoir

- Upgradation of SACS Software: SACS Software has been upgraded to new edition SACS CONNECT V16.0. Upgraded version of software comprises of latest codes for analysis along-with enhancement in user interface.

- Automation of M&C Laboratory with state-of-the-art Abrasive Cutting Machine for metallographic samples: IPEOT has procured Abrasive Cutting Machine for metallographic samples with automatic cutting provision.

- Upgradation of PHAST/SAFETI software: A new version of PHAST/SAFETI software (from version 8.61 to 8.7) with additional features installed for performance enhancement of Quantitative Risk Assessment studies includes CFD capabilities for modelling Jet Fires.

- Heated Centrifuge procured for IPEOT laboratory up-gradation.

3. Papers published / presented: 24

4. IPRs

A. Patents Filed:

02

- Pour point depressant composition for waxy crude oil

- Synthesis of silica-based hydrophobic particles using a single organosilane

B. Patents obtained:

06

- Composition for Completion Fluid for use in ultra-high Pressure and high temperature applications

- Production Enhancement Apparatus for a Sucker Rod Pump

- Fiber Reinforced Plastic (FRP) Fencing System for Oil & Gas Well Head Areas in On land

- Apparatus and method for preventing liquid from overtopping a bund wall

- Debris catcher for offshore process platforms

- A Method of Fuel Gas Reduction for Indirect Bath Heater (IDBH)

C. Copyrights registered:

03

PEBUL SOFTWARE

- Lift selection software specifically focussing on gas well deliquification.

Oil field analyser

- It provides a single platform to feed all well related data at single place which can be shared across the organization / Producing Asset. Ability to determine Production Variance-Maximum, minimum and percentage variation of oil, liquid and gas rate is one of the salient features of the software, which could be useful to check the performance of a particular well.

DAIL Software

- Dynamic Application of Intermittent Gas Lift (DAIL)” is mechanistic software based on first principle which carries out dynamic simulation of the Intermittent Gas Lift process to predict, analyze and optimize its performance. As a Physics based model, it performs a realistic simulation of the transient physical processes in an Intermittent Gas Lift cycle.

Collaborative R&D projects

- Several collaborative projects in collaboration with eminent institutions like IITs, NML Jamshedpur and ARI Pune